3D Services

What is Prototype?

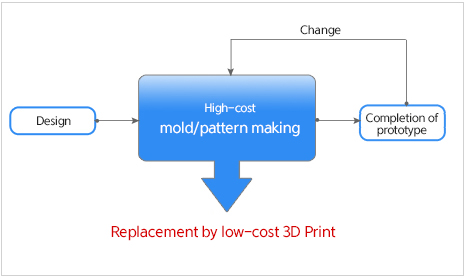

It is the step of the process for checking the quality and function of the finally developed

product prior to mass production step. The service of this company uses

3D Print to save the cost for prototype.

Work Process

Advantages of 3D Print based prototype

- ¯ No need of high-cost mold/pattern making

- ¯ Product completion through changes in the design step (optimized development process)

Types of 3D Print based prototype

3D Printing (RP)

A product is developed in the way of layering one by one in the direction of Z-axis. It is possible to make a prototype immediately without any limitations of product shape, like undercut.

Materials

Digital Materials / Engineering Plastic Materials (ABS-like) / Heat-resistant Materials (High Temperature) / Transparent Materials

Hard & Opaque Materials /

Polyprotylene Materials (Rubber-like)

Types

- Fused Deposition Modeling (FDM) Method

- In this method, a diversity of engineering plastic (ABS, PC-ABS, PPSF, etc.) with filament shape is heated at a high temperature head, and then is extruded through nozzle. After that, a material is extruded over a solidified layer so as to shape a product.

- ¯ Advantage

Since plastic materials such as ABS and PC are used, there are excellent durability and heat-resistance. In addition, plotter is applied so that dimension precision is excellent. Therefore, the method is suitable for making assembly parts. - ¯ Equipment Image

- ¯ Product Same Image

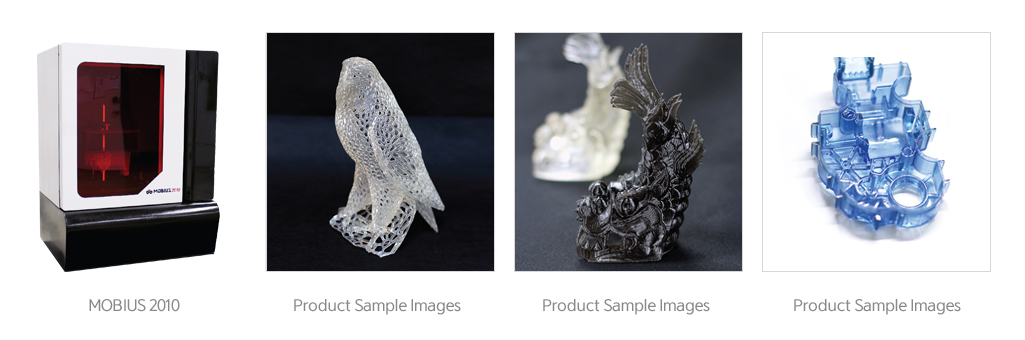

- Stereolithography(SLA) Method

- In this method, laser beam is shot at a tank with photopolymer liquid in order for hardening. A support of layers printed matters is shaped in a building platform. When layered one by one, the building platform moves and shows a position for the next layering and thereby a printed matter is complete.

- ¯ Advantage

Higher precision than FDM method; excellent surface profile and fast speed - ¯ Equipment & Product Sample Images

NC Processing

Cutting process using NC Machine makes it possible to make a product with excellent surface profile and dimension precision.

Materials

ABS-like / PC-like / Acrylic-like / Metal-like

Vacuum Casting

With the use of a product made by 3D Print, it is possible to produce small-quantity and multiple-type products per mold through silicone mold..

Work Process

1. CAD/CAM 2. NC Master or Master Making 3. Silicone (or Epoxy) Mold Making

4. Vacuum Casting

5. Post-processing & Surface Processing

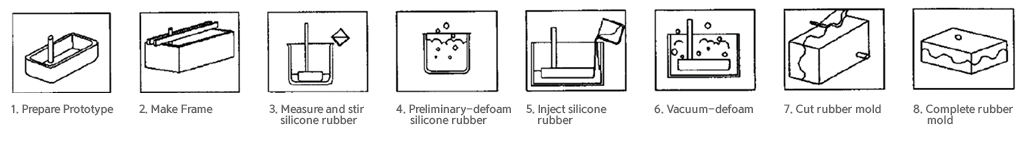

¯ Mold Making Process

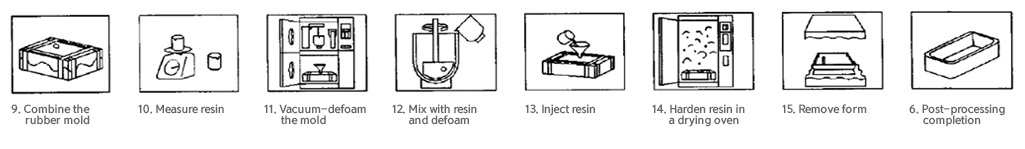

¯ Vacuum Casting Product Making Process

Materials

ABS-like / Nylon-like / Urethane-like

Features

¯ Time and cost saving

¯ A small number of products by one mock-up making

¯ Free choice of mold materials, such as metal, wood, and plastic

Application areas of mock-up making

- 1. Concept Model

- 2. Functional Prototypes

- 3. End – Ues Part

- 4. Manufacturing Tools